粒子钢,也叫水洗铁,是炼钢后的下脚料,经过多次磁选水洗生产出来的,普碳钢,出水率70%-95%,用于电炉铸钢件和冶炼钢坯,可代替废钢,易于熔化,节省电力,比废钢要低300-400元。

国际形势来看,一些发达利用节能环保方面的技术优势,已在国际贸易中制造了较高的绿色技术壁垒。国内形势来看,面对严峻资源环境约束,“十三五”时期是我国节能环保产业发展难得的历史机遇期,发展前景广阔。据有关部门测算,到2016年节能潜力超过4亿吨标准煤,可带动上万亿元投资;节能服务总产值可突破3000亿元;产业废物循环利用环境服务总产值将达5000亿元规模。

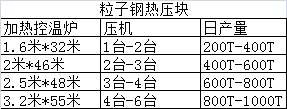

鑫虎粒子钢热熔压块机工艺流程描述

Process deion

钢销、钢渣粒子钢、钢渣精粉、高品位铁粉还原等液压压制成型系统工艺是将钢销、钢渣粒子钢由上料机加入到系统设备,由低温对流烘干器和调温器进行温度控制,对钢渣粒子钢进行烘干,然后经中间转运器输送到液压成型机,经液压按需求调整液压压力(0-315bar动态可调)压制成型后将压制好的粒子钢块由装载机吊运至成品库,期间部分热量由高效换热器进行回收利用,设计有除尘系统对生产过程中产生的废气、粉尘等污染进行环保处理。

七、钢渣粒子钢液压压制成型系统的技术优势

Technical Advantages of Hydraulic Pressing Molding System for Steel Slag Particle Steel

1、粒子钢铁水降低率低

Low reduction rate of particulate molten iron and steel

系统采用特殊调节手段对粒子钢上料、液压压制成型等方面进行自动化控制,粒子钢在此过程中氧化率很低,因此与原料相比,粒子钢成型后含铁量降低幅度可以控制在2%以下。

Particle steel feeding and hydraulic pressing are controlled automatically and accurately by special adjusting means. The oxidation rate of particle steel is very low in this process. Therefore, compared with raw materials, the reduction of iron content after particle steel forming can be controlled below 2%.

2、粒子钢质量耗损率低

Low mass loss rate of particulate steel

此设备采用高效收尘措施,小粒级粒子钢直接返回烘干二段,且系统封闭性较好,因此,系统粒子钢几乎没有损耗。

This equipment adopts high efficiency dust collection measures, small particle steel directly returns to the second drying stage, and the system has good closure, so the system particle steel has almost no loss.

3、系统降低能耗

System Reduction of Energy Consumption

系统采用全自动化进行控制,对生产过程中的各个环节进行控制和先进的液压伺服装置,在运行过程中电耗低,系统总功率比常规系统降低20%左右。

The system uses full automation for precise control, precise control of all links in the production process and advanced hydraulic servo device. In the operation process, the power consumption is low, and the total power of the system is reduced by about 20% compared with the conventional system.

4、系统造价较低

Lower system cost

系统设计中将烘干过程分级设计,系统尺寸大幅度降低,与常规设计相比,本系统造价降低约30%左右。

In the design of the system, the drying process is graded and the size of the system is greatly reduced. Compared with the conventional design, the cost of the system is reduced by about 30%.

5、系统事故率低

Low system accident rate

通过模拟计算和自动化系统预警和调节,设备某一环节出现故障或系统检测传感器参数有异常时会及时进行报警和优化设备运行,系统作业率大幅度上升。

Through analog calculation and automatic system early warning and adjustment, the system will alarm and optimize the operation of the equipment in time when a fault occurs in a part of the equipment or the parameters of the system detection sensor are abnormal, and the operation rate of the system will increase greatly.

6、 系统流程简单,运行稳定性好

The system process is simple and the operation stability is good.

系统流程设计非常简洁、顺畅,调节手段灵活,系统运行稳定性很高。

System flow design is very simple, smooth, flexible means of regulation, system operation stability is very high.